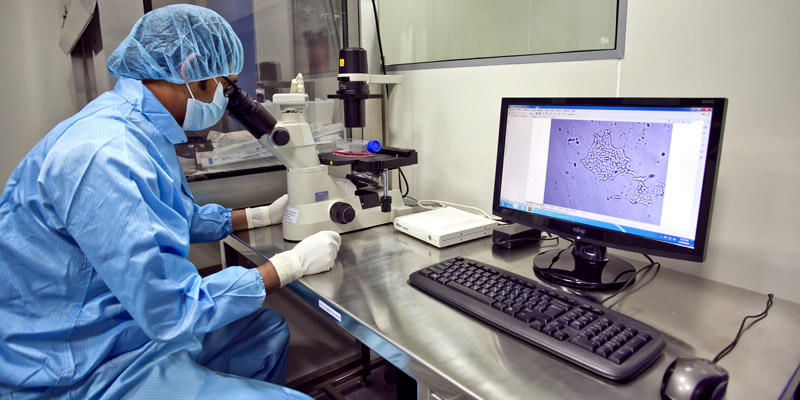

R & D facility

Incepta Vaccine Ltd has state of the art Research and Development facility with 35 scientists who are working round the clock for developing product first in class and best in class. The facility is equipped with modern technology and laboratory settings for new vaccine production. The facility is divided in 4 parts:

- Bacterial R&D area- Divided in infectious and non-infectious area.

- Viral R&D area – Divided in infectious and non-infectious area.

- Formulation Area.

- Common area – This include washing and sterilization area, decontamination area, chemical store and dispensing area and cell bank storage area.

Total clean, controlled area in R&D is 10,000 square feet. Each area is provided with dedicated independent HVAC system with various classified rooms. The AHUs are qualified as per WHO guidelines with double Bag in Bag out system along with double HEPA filters.

R&D facility has the following activities

- Cell banking and characterization – Bacterial cells and Virus cell lines

- Fermentation of wild or recombinant bacteria.

- Fermentation of yeasts

- Cultivation of cell lines and viruses

- Purification of proteins and polysaccharide

- Purification of viruses by removing host cell contaminants

- Conjugation of polysaccharide with carrier proteins

- Formulations